Category:

Recycling Systems

Machine type:

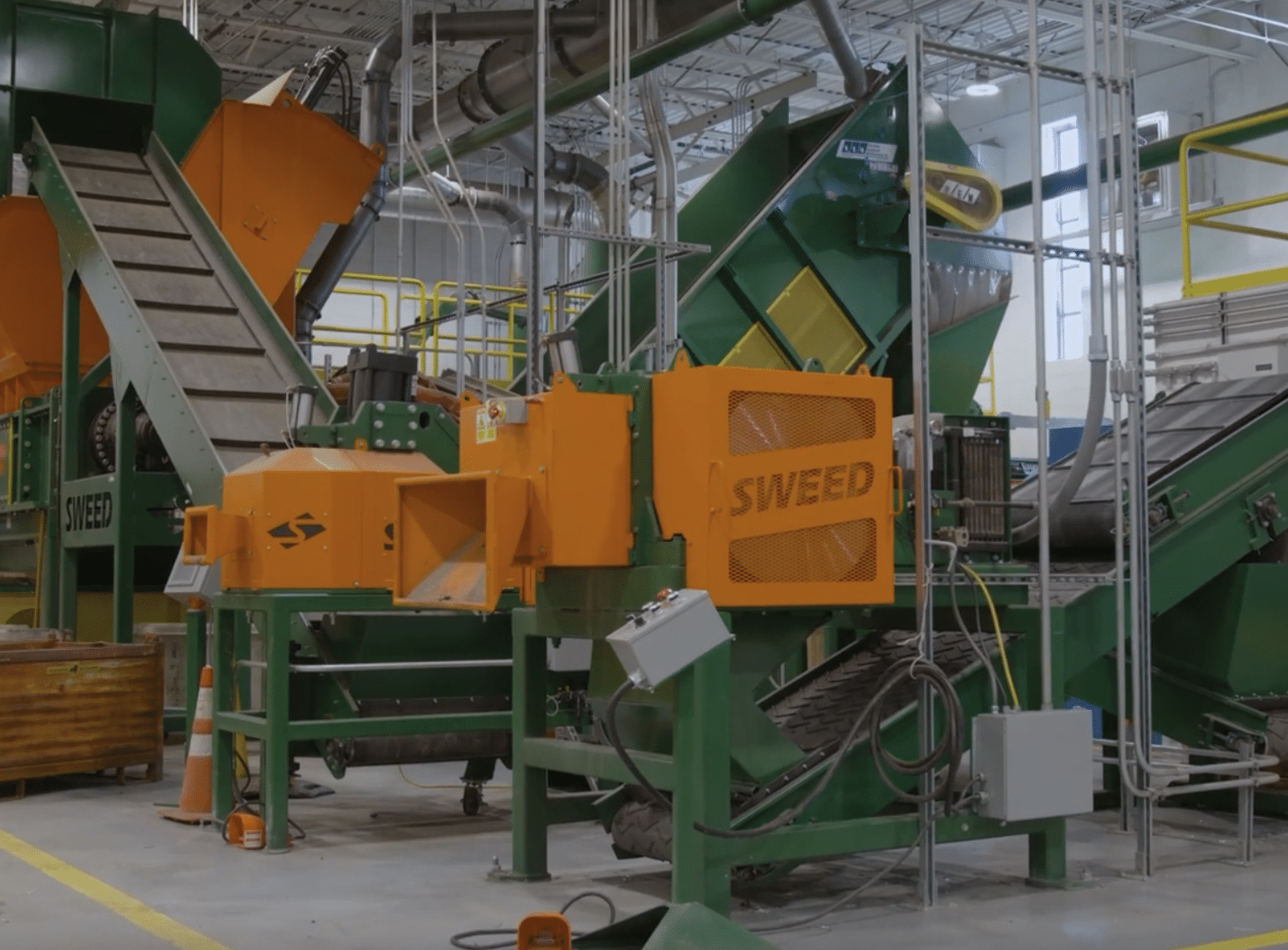

Chopping Line

SWEED S2000+

Elevating Copper Recovery: Low-Yield Wire & Simultaneous Copper-Aluminum Processing, Up to 2,000 Pounds per Hour.

Introducing the S2000+ by SWEED, a specialized wire chopping line designed to excel in processing a wide range of challenging scrap materials. This cutting-edge system is tailor-made for low-yield wire and cable, notorious for their fine, hard-to-process hairs. Unlike conventional copper recovery methods that often result in significant copper loss, the S2000+ is equipped with a turbo mill, revolutionizing the processing of #2 wire and ensuring an exceptional copper recovery rate.

But the S2000+ doesn’t stop there—it’s versatile enough to handle an array of scrap materials. From all types of wire and cable to ASR, wire harnesses, and more, this system ensures efficient processing across various materials. What’s more, with dual dedicated air tables, it can simultaneously process both copper and aluminum materials, enhancing your efficiency and scrap metal processing capabilities to unprecedented levels. When it comes to tackling tricky scrap materials while optimizing copper recovery, the S2000+ sets a new industry standard.

Construction Features

The SWEED S2000+ Wire Chopping Line offers a versatile solution for wire chopping needs. Its standard features include a range of SWEED equipment, all built with SWEED’s high-quality standard construction for lasting durability and efficiency.

PCR1048 Prechopper

Conveyor w/ Magnetic Ferrous Separation

SG1826 Granulator

TM1815 Turbo Mill

(2) 3G Airtables in series Density Separation

Single deck sifter and auger for plastic output

Outdoor 8K CFM Dust Collector

High purity end results

Durable & built to withstand harsh environments

Simple and minimal maintenance required

One-year warranty

Made and supported in the USA

Optional Features

The SWEED S2000+ Wire Chopping Line offers a range of optional features and customizations, including additional components and tailored solutions, allowing buyers to adapt the system to their specific requirements.