Category:

Wood Products

Machine type:

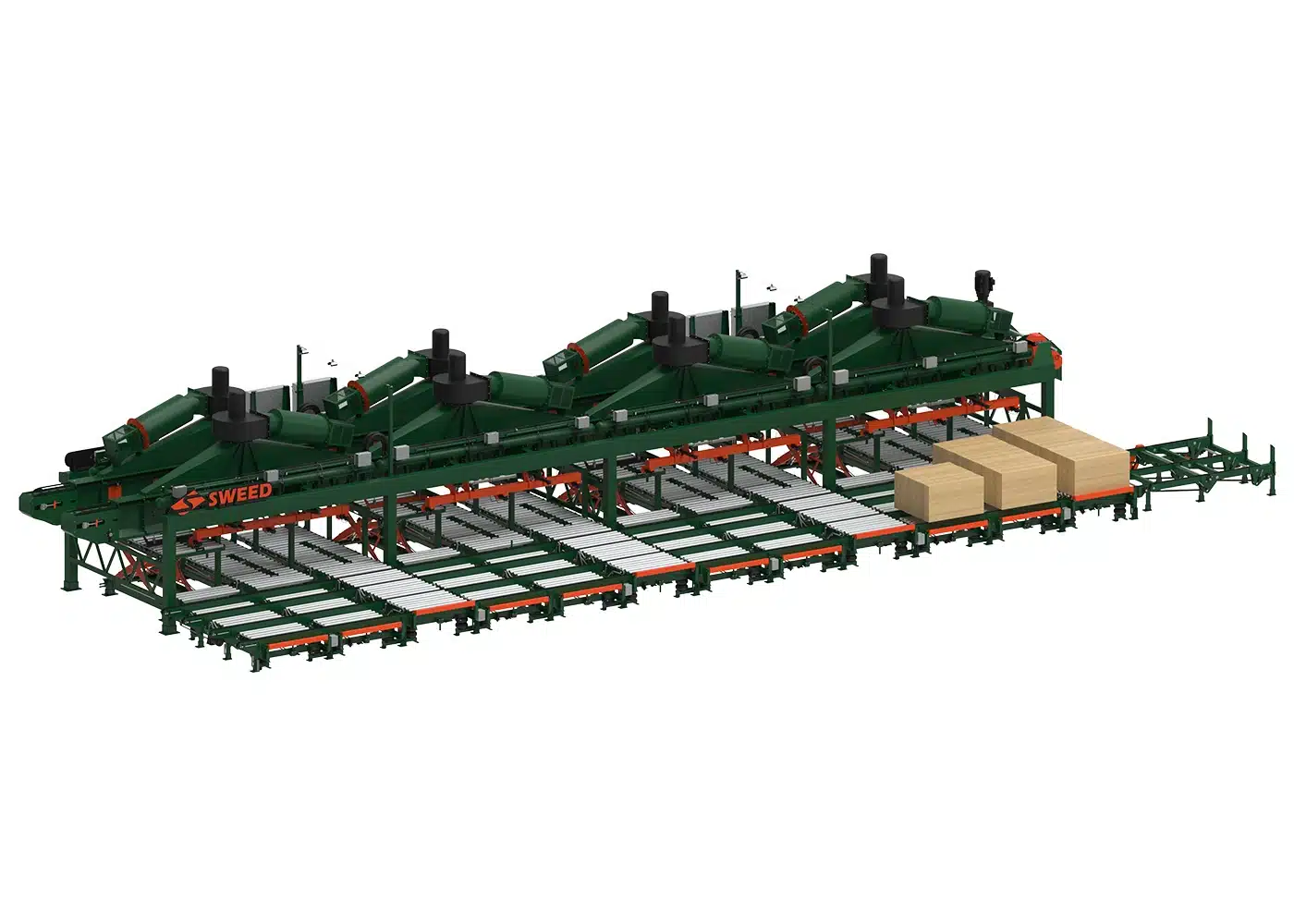

Veneer Stackers

Green, Dry, and Random Veneer Stackers

Custom Solutions for the Toughest Veneer Stacking Applications.

SWEED provides high speed automated handling solutions for all of today’s toughest veneer stacking applications; including green, dry, random, half and full-sheet stacking, for 4’, 8’, 9’ and 10’ veneer. As well as a custom solution for multiple veneer lengths.

SWEED’s stackers are designed with functionality and maintenance in mind. They are built to perform under demanding conditions at today’s high-production requirements. SWEED stackers come equipped with proven Allen-Bradley ControlLogix programming developed for all wet and dry applications.

Construction Features

At SWEED, we carry forward the Jeddeloh brothers’ legacy of relentless commitment to construction, craftsmanship, durability, and reliability in our wood products equipment. Designed to perform 24/7, our solutions are renowned for their robust construction, thriving in demanding environments. Our material handling solutions seamlessly enhance productivity and safety, providing the flexibility to optimize your operations, all while maintaining the enduring tradition of exceptional quality that defines SWEED.