Category:

Recycling Systems

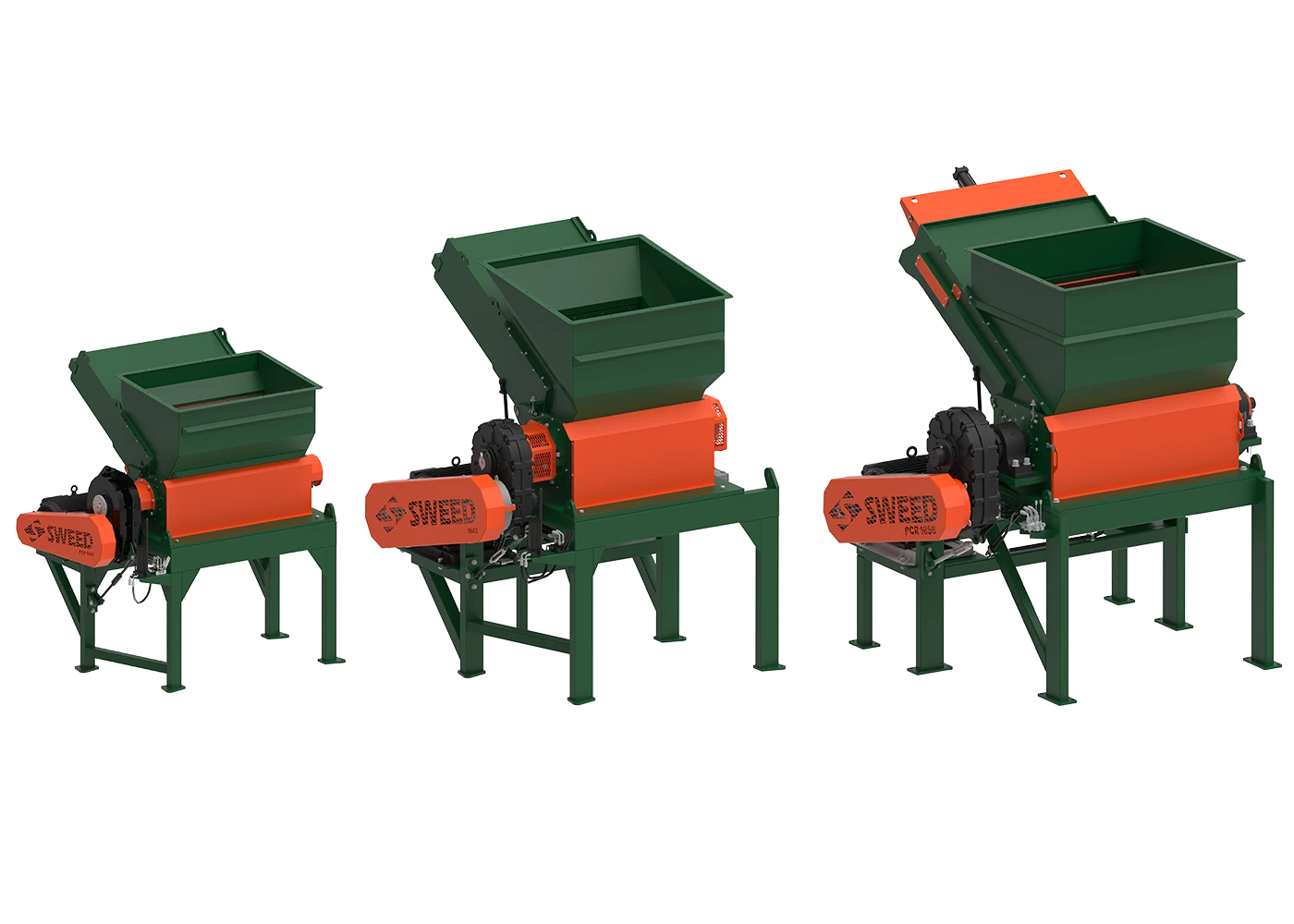

Prechoppers: PCR Series

Built for Durability and Reliability, Offering Heavy-Duty Construction in a Compact Size.

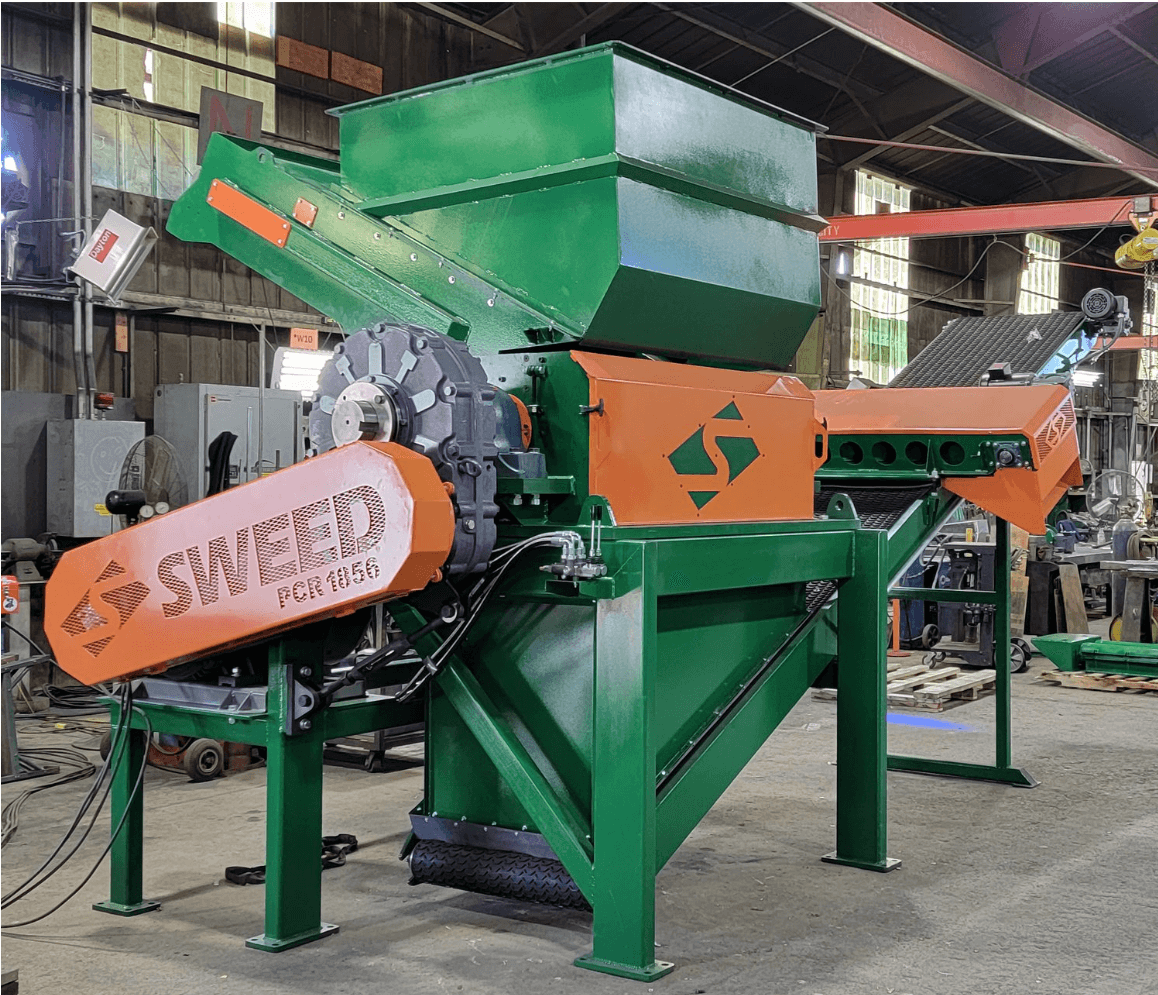

SWEED’s Prechopper is a single-shaft shredder that provides rapid reduction of ferrous and non-ferrous scrap material.

The closed rotor design allows bulk feeding without overloading the machine. Once the material is loaded into the hopper, it’s fed into the rotor using a hydraulic ram. The chopped material then drops into a hopper located under the unit or conveyed into a separate container or granulator for further processing.

SWEED’s Prechopper is built for durability and reliability and offers heavy-duty construction in a compact size. Interchangeable screens are available for material size control. The hydraulic powered carriage allows the Prechopper’s screens to be changed quickly and easily.

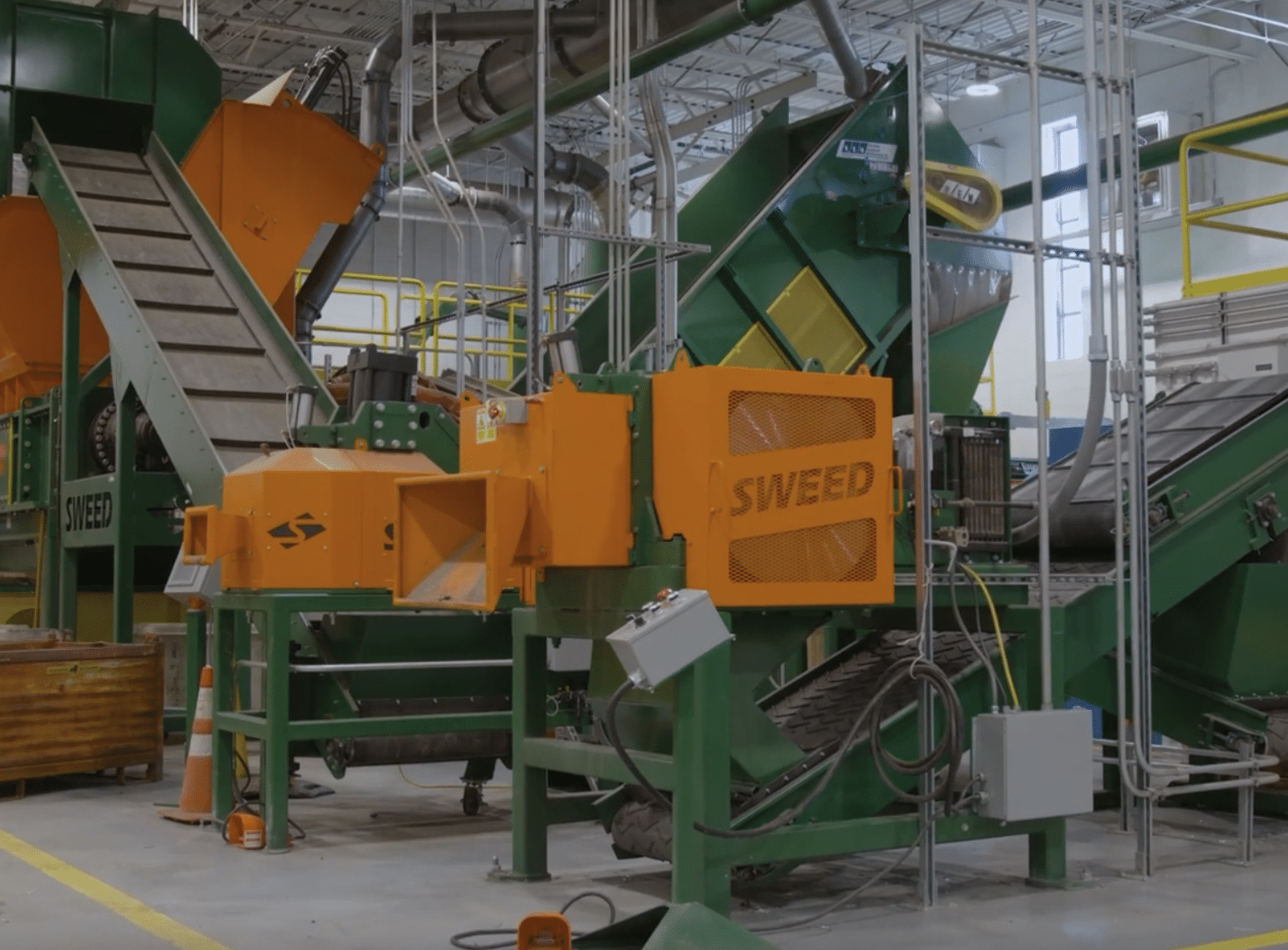

SWEED offers Prechoppers in multiple sizes, depending on volume. Each are designed to stand alone or can be placed in-line with a SWEED Separation System.

Construction Features

SWEED systems offer robust designs and seamless integration capabilities that optimize scrap reduction and nonferrous metal recovery through innovative technology. This results in maximum scrap metal recovery and compaction, simplified system maintenance, and durable construction.

Material Reference

The recommended prechopper shredder model is determined by the type of material needing to be shred, the volume being processed, and requested custom features. Please consult a SWEED representative to determine the appropriate prechopper for your application. The following are materials commonly processed through the SWEED shredders:

Off-Spec Wire and Cable

Auto Shredded Residue

Scrap Plastic Materials

Scrap Electronic Cable

Electronic Scrap

Scrap Telecommunication Wire and Cable

And More!

Construction Features

SWEED prechoppers are well-known for their robust construction and ability to endure demanding environments. SWEED prechoppers offer a reliable and efficient solution for preshredding bulk scrap materials while prioritizing durability, safety, and user-friendly operation.