Enhance Your Production Efficiency

Maximize your mill’s productivity with SWEED’s specialized material handling solutions. From high-speed veneer dryer systems to automated panel handling, our equipment streamlines production, improves safety, and optimizes every phase of veneer and panel manufacturing.

Today’s mills face increasing demands for production efficiency while managing critical throughput requirements. SWEED’s integrated solutions enhance:

Veneer drying operations

Panel grading and handling

Green, dry, and strip stacking

Material transfer systems

Featured Solutions

Engineered Excellence for Modern Mills

SWEED's comprehensive line of material handling equipment addresses the specialized needs of modern panel and veneer operations. From innovative dryer infeed systems to automated stackers, we provide field-proven technology that enhances productivity while maintaining the highest production standards.

Request A Quote

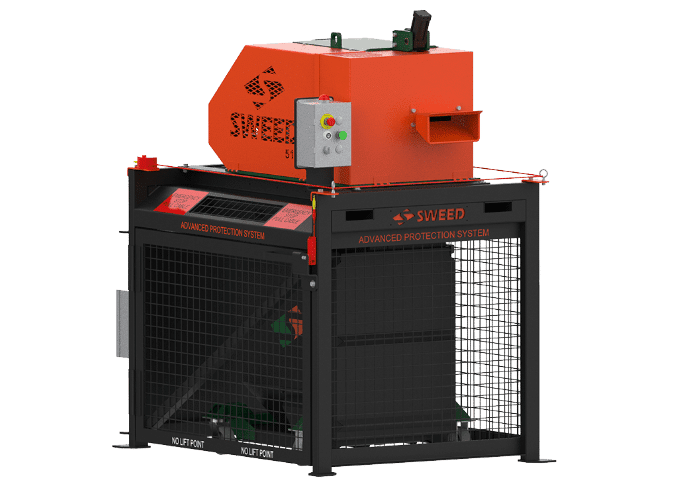

Smart Pause Dryer Infeed

Our revolutionary Smart Pause technology provides veneer dryer infeed operators additional time to address feeding issues while maintaining 100% dryer fill rate. This innovative system allows operators to pause the feeder for up to 20 seconds upon a misfeed, without stopping the dryer, maximizing production efficiency while eliminating gaps.

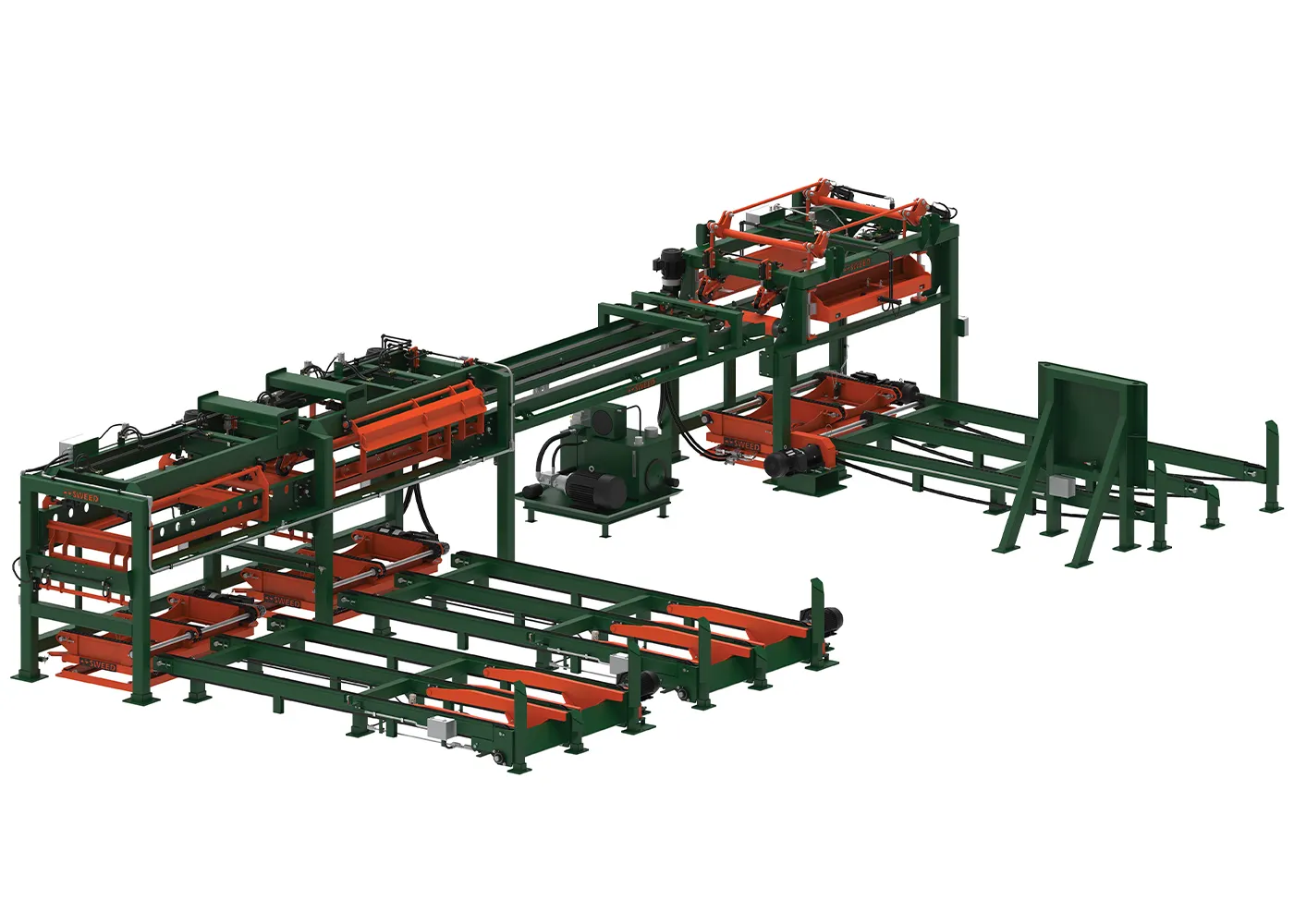

Versatile Veneer Stacker

A breakthrough solution for mills handling multiple veneer sizes. This innovative stacker easily adjusts to handle any combination of 4′, 8′, 9′, and 10′ veneer with simple push-button changeover in less than a minute. The split plenum design dramatically improves accessibility and maintenance while ensuring superior stack quality.

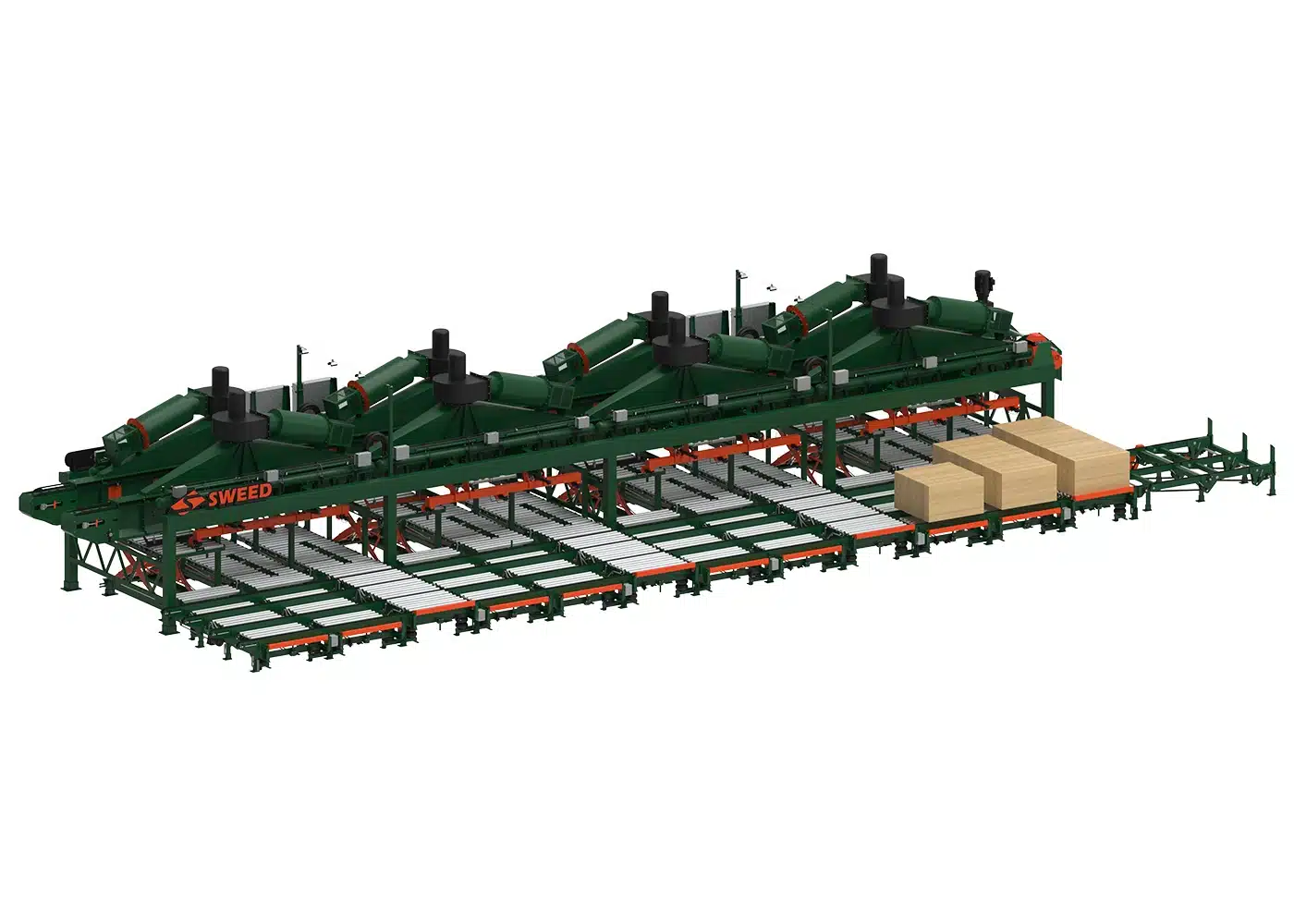

Grading Line System

Our advanced panel grading line seamlessly integrates into your manufacturing process, efficiently sorting and grading materials using mechanical feed mechanisms and dual bin stacker assembly. This smart solution enhances product quality while minimizing downtime for optimal production.

Applications By Process

Veneer Drying

Smart Pause technology

Automated feed systems

Maximum dryer fill rate

Precision material handling

Panel Processing

Automated grading systems

Efficient material transfer

Production optimization

Safety-focused design

Stacking Operations

Multiple size handling

Green, dry, and strip stacking

Enhanced stack quality

Automated solutions

Safety & Automation Features

SWEED's solutions integrate seamlessly with modern mill automation requirements. Each system incorporates essential safety features that protect workers while maintaining production efficiency, significantly reducing workplace hazards while supporting continuous operations.