Streamline Your Operations

Optimize your warehousing operations with SWEED’s innovative banding chopper solutions. From distribution centers to freight terminals, our scrap chopper equipment enhances workplace safety, reduces operational costs, and transforms packaging waste into recyclable assets.

Warehousing and distribution facilities face daily challenges managing large volumes of banding and strapping materials that create hazards and waste valuable space. Whether you need a steel band chopper for receiving areas or a strap chopper for shipping stations, SWEED’s efficient processing solutions help facilities manage:

Steel banding with clips

PET strapping

Scrap strapping debanded from secured pallets

Tangled strapping that creates trip hazards for employees

Featured Solutions

Purpose-Built Equipment

SWEED's range of scrap banding and strapping choppers address the unique challenges of modern warehousing operations. From receiving docks to shipping areas, we provide proven scrap chopper solutions that enhance safety, improve housekeeping, and support sustainability initiatives while reducing disposal costs and maximizing recycling revenue.

Request A Quote

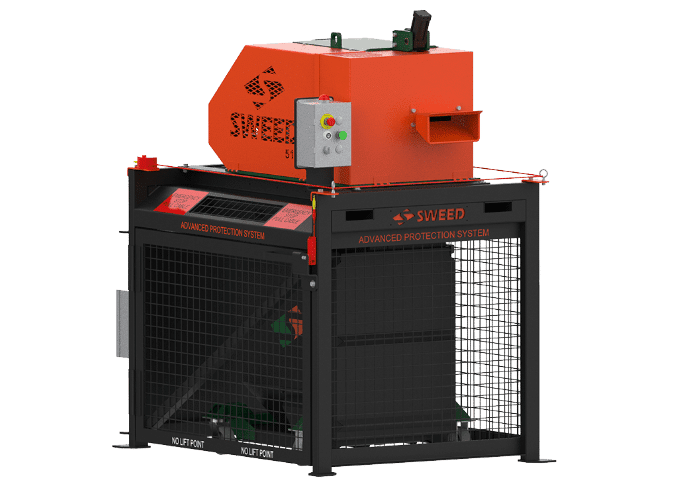

Model 450 DDX Scrap Chopper

Our flagship strap chopper solution for high-volume distribution centers delivers exceptional performance in demanding environments. This versatile scrap chopper efficiently processes both steel banding and plastic strapping while offering simple operation and maintenance. The dual-driven feedworks ensure consistent processing, while the compact design allows for strategic placement throughout your facility.

Model 300 Scrap Chopper

Designed for distribution environments handling lower scrap volumes, the Model 300 offers an economical solution for plastic strapping, steel banding and other lightweight scrap materials. Its compact design makes it an ideal addition to individual processing stations, helping smaller operations improve waste management efficiency across their facility.

Applications By Process

Receiving Operations

Immediate banding removal

Reduced dock congestion

Enhanced safety protocols

Efficient material flow

Storage Areas

Strategic waste management

Space optimization

Improved housekeeping

Safety compliance

Shipping Operations

Quick processing of materials

Reduced cleanup time

Organized workspace

Enhanced productivity

Safety & Automation Features

SWEED's scrap chopper solutions prioritize workplace safety while streamlining operations. Each banding chopper unit incorporates essential operator protection features and helps keep workers safe by reducing exposure to potential hazards, including tripping hazards and exposure to sharp banding and strapping materials. Additionally, SWEED's engineers can provide customized chopper solutions to further improve operator safety.

Learn More