Auto Wire Harness Choping Line for Copper Recovery

In SWEED’s latest scrap wire test, our engineers processed auto wire harness in our on-site demo system.

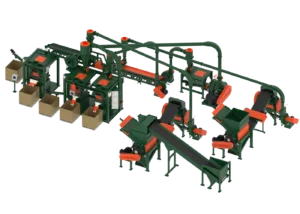

In the video demonstration provided in this post, you’ll see scrap wire harness being broken down by our prechopper, then it travels to the granulator for sizing. After the granulator, the mixed chopped material is exhausted to the turbo mill where the balled up copper strands are completely liberated from the plastic sheathing before being separated. The material then travels to the first air table where air and gravity further help separate the plastic and fluff from the valuable copper. Additional processing for finer granules are separated on the second air table, and the sifter provides another opportunity to separate the copper fines that may still be stuck to the plastic.

SWEED wire chopping systems can process from 1,000 to over 20,000 pounds per hour and efficiently separate all types of wire from power transmission to communication cable, low yield wire, ACSR, BX Cable, wire harness, and more. SWEED also builds systems to recover ASR, ACR, and other mixed non-ferrous materials.