From Hazard to Asset: How Scrap Choppers Transform Steel Banding Management

Steel banding, while essential for securing loads during transport and storage, presents a significant workplace hazard when it comes to disposal. Every year, facilities face expensive equipment damage and worker injuries from improperly handled banding waste. However, scrap choppers transform how industries manage this challenging material, turning a workplace liability into a valuable recycling stream.

The Hidden Costs of Steel Banding Waste

Without proper management, discarded steel banding creates numerous challenges:

- Workplace injuries from sharp edges and spring-loaded coils

- Damaged equipment when banding becomes entangled in forklifts

- Increased insurance premiums from accidents and claims

- Storage issues and cluttered work areas

- Lower recycling value due to bulky, unprocessed material

- Increased disposal fees

The SWEED Solution

SWEED’s line of industrial scrap choppers, including the Model 300 for light metal applications and the Model 450 DDX for higher volumes, efficiently process steel banding into uniform, manageable pieces. These machines can handle narrower widths of steel banding, eliminating the need for manual preprocessing.

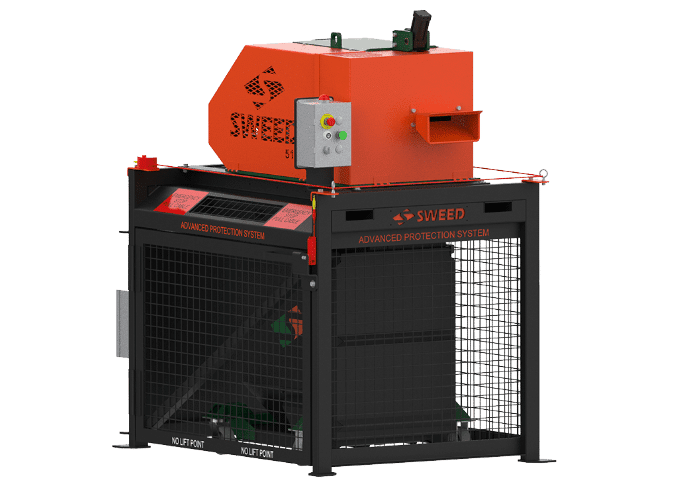

For facilities dealing with wider steel banding with clips and higher volumes, the Model 510 XHD scrap chopper offers enhanced capabilities. This robust unit features large dual-driven feedrolls and a higher-horsepower motor, ensuring improved feeding efficiency when processing stout materials.

Beyond Safety: The Financial Benefits

Processed steel banding typically commands higher recycling prices compared to loose, tangled material because compacted and prepared banding is easier to handle and recycle. Scrap choppers can:

- Reduce storage space requirements by up to 80%

- Lower transportation costs through increased material density

- Minimize labor costs associated with repeated handling of unprocessed material

- Generate cleaner, more valuable recycling streams

- Decrease workplace accident rates and associated costs

Recycling Benefits

Did you know that steel is infinitely recyclable?! Unchopped steel banding is difficult to store and even more difficult for recyclers to process. With a scrap chopper you can:

- Prepare scrap steel banding for recycling

- Increase the value of your prepared scrap steel banding, due to its recycling readiness

- Keep this valuable ferrous scrap commodity out of the landfills

- Help you achieve your recycling and sustainability goals

Choosing the Right Solution

When selecting a scrap chopper, consider:

- Volume of material to be processed

- Size of steel banding

- How many areas in your facility that generate scrap banding

- Future growth requirements

SWEED’s range of products, from the light-duty Model 300 to the industrial-grade Model 5703 XHD, ensures solutions for operations of any size.

Workplace Safety and Training

While scrap choppers significantly improve workplace safety, proper training remains essential. SWEED’s machines include various safety features such as:

- Infeed restrictor plates

- Emergency stop mechanisms

- Optional advanced protection systems

- Optional machine-in-use indicators

Conclusion

Modern scrap chopper technology has improved the management of steel banding, transforming a workplace hazard into a valuable asset. By implementing the right solution, facilities can improve safety, increase efficiency, and generate additional revenue through enhanced recycling operations. As sustainability becomes increasingly important, proper management of steel banding waste represents a key opportunity for operational improvement.

Looking to transform your facility’s scrap steel banding management? Contact SWEED to learn more about their comprehensive range of scrap choppers and recycling solutions.