How Sweed Solved the Tube Scarf Problem

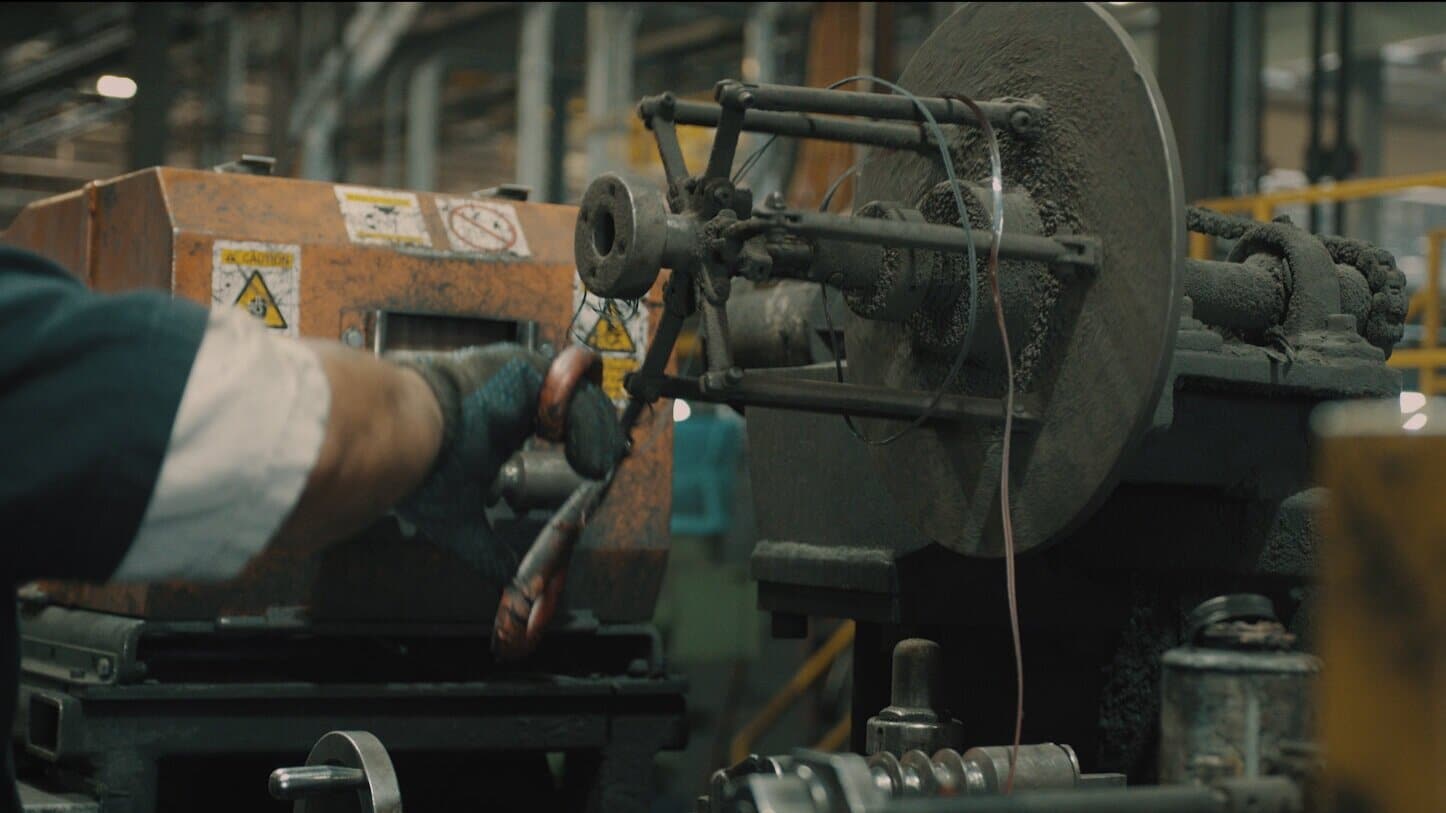

Since SWEED’s founding more than 70 years ago, we have been filling industry niches and addressing our customers’ needs with innovative, well-crafted machines. In the late 1990s, we started to receive many requests for something that could help mills process tube scarf better than the existing solutions. The problem with the old way of processing tube scarf is, the material is incredibly hot and sharp and using a traditional winder required a lot of human interaction, which posed a great risk of burn and cuts. “We knew our customers needed a safer and more efficient way to process this material, so we went to work on making a new solution,” says Eric Schmidt, an engineer at SWEED.

To solve the tube scarf problem, Schmidt began work on a machine that could process the material without having so many points of human contact. “When mills wind the scarf, the user needs to grab it with tongs and place it in the winder,” Schmidt explains. “Then, when the winder is full, they need to lift the hot, sharp, and heavy roll off of it and place it into a hopper.” To create a solution that eliminated many of those points of contact and inefficiencies, Schmidt worked closely with customers to refine the test machines that he had developed at Sweed. “It was important to test our machines in actual mills to see how they would work outside of a simulated environment. We discovered many opportunities for improvement by doing so,” Schmidt says.

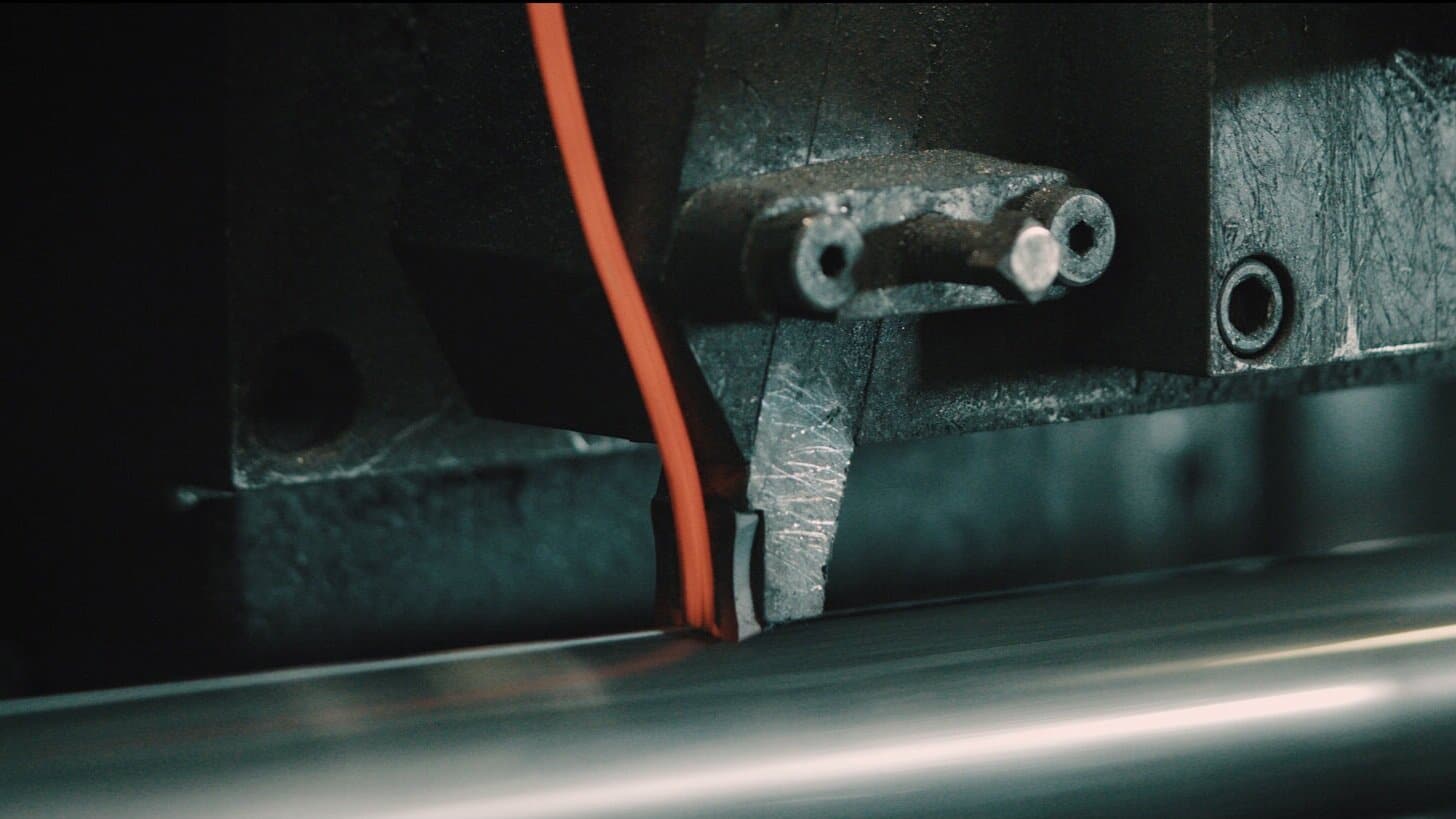

All of that work produced the SWEED TS450, an O.D. tube scarf chopper. “User safety was our primary concern in designing this machine,” Schmidt says. “The scarf chopper relies on the user feeding it once and will continuously pull the scarf in itself as long as the scarf knife stays in contact with the weld.” The chopper cuts the scarf into 2-3” pieces, which are conveyed out to the hopper. The beauty of the tube scarf chopper is where there used to be 3 or more points of human contact with hot, sharp metal, there is now only one simple step to initially feed the scarf into the chopper. This causes a marked increase in mill safety, while also decreasing production downtime that can occur as a result of the winder needing to be unloaded and changed when it gets full.

These aren’t the only benefits of the TS450 chopper, however – like all SWEED machines, it was built to integrate easily into our customers’ existing systems, and it requires minimal space for installation. Not only does the chopper work well in slower line speeds that are around 300-450 ft/min, but it can also accommodate higher speeds of 650 ft/min or more. The TS450 also easily adjusts to the natural variations of thickness of the scarf string and can handle a wide range of wall thicknesses up to ¼”. “The main reason behind every feature and update is our customers,” says Henry Rueda, an engineer who helped bring the TS450 to the next level. “Processing tube scarf is not an easy thing to do, so we listen closely to our customers’ needs. From the initial design, we have expanded the infeed opening and increased the size of the feedrolls to make it as easy as possible to get the scarf into the chopper.” Beyond that, the TS450 now has a redesigned feedroll for heat dissipation including forced air induction that keeps the feedrolls cooler while processing 1,600-degree tube scarf. Through customer collaboration and design contributions from engineers like Rueda, the TS450 has been continuously innovated for improvement since its inception and now accomplishes its work better than ever.

With all of our machines, our goal is to help our customers accomplish their work as safely and easily as possible, and the TS450 tube scarf chopper is no exception. From a starting design that greatly reduced the chance for workplace injury while increasing processing efficiency to new updates and improvements that allow it to integrate seamlessly into existing systems, our TS450 truly has solved the Tube Scarf Problem.