Sweed Tube Scarf Chopper Testimonial From Bull Moose Tube

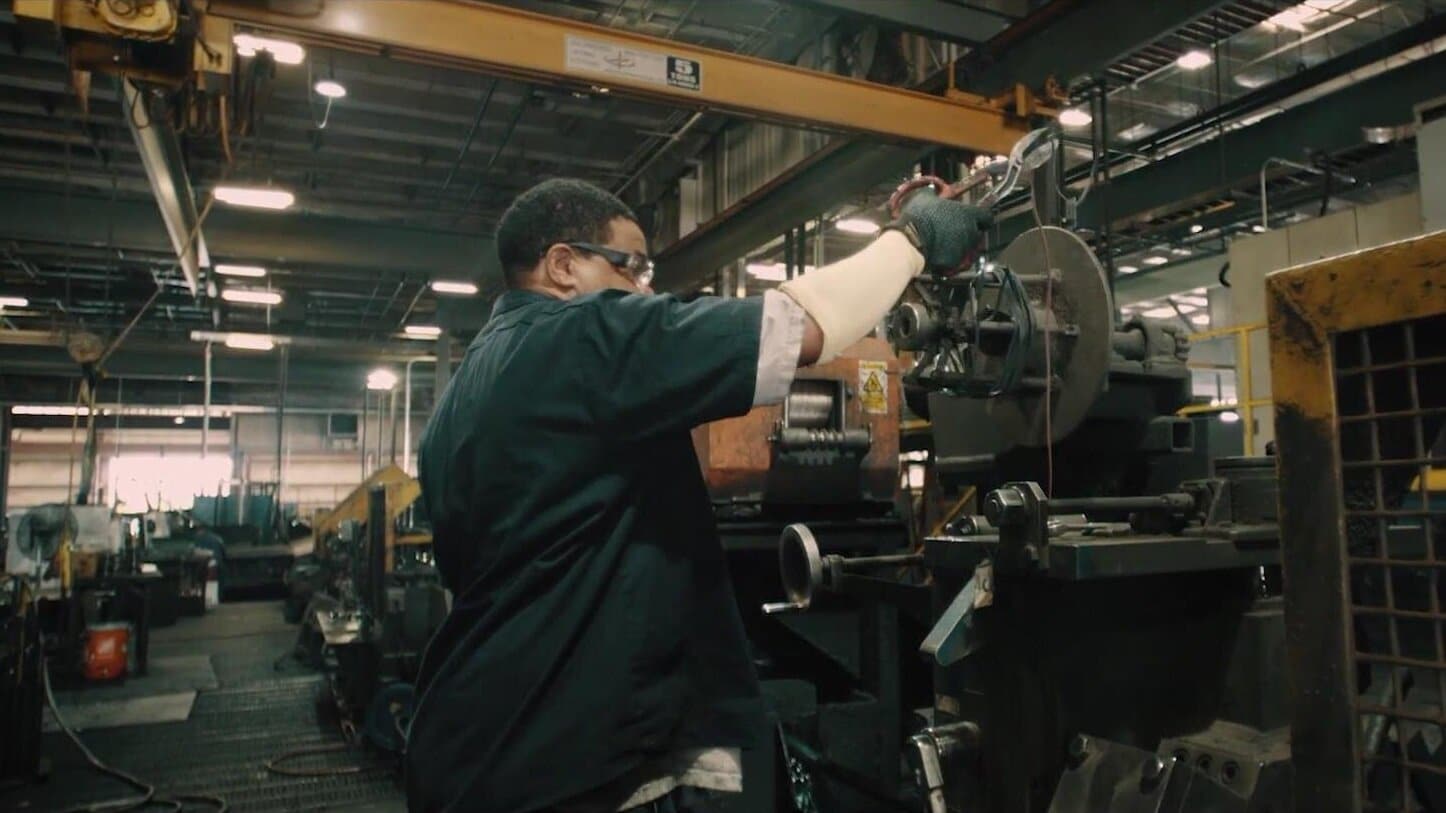

Based out of Casa Grande, Arizona, Bull Moose Tube and Pipe is a manufacturer that supplies their products to companies in a variety of industries across the world. In their 172,000 square foot facility, they manufacture and process welded tube, which means they have to deal with a lot of O.D. tube scarf as a byproduct of their manufacturing. Tube scarf is incredibly hot and sharp, and traditional processing procedures present many opportunities for user injury and line downtime.

To help them process this tube scarf more safely and efficiently, they worked with Sweed to design a custom solution – the TS450 tube scarf chopper. “The Sweed scarf chopper does increase efficiency for us because it is easier for the employee to feed the scarf into the chopper versus the winder,” says Erick Charboneau, Plant Manager at Bull Moose Tube and Pipe. Before partnering with Sweed, Bull Moose Tube, like many tube mills, used a winder to deal with tube scarf, which caused many opportunities for hand injuries. The operator had to use a tool to grab and physically wrap the hot, sharp tube scarf onto the winder and then remove the spool by hand once it was full. Workers would get cuts, snags, and burns, from trying to wind the scarf while it was moving at line speed and there was ample opportunity for errors. “[The chopper] will let you continually feed the scarf into it,” Charboneau explains, which eliminates the risky points of contact from the winder and cuts down on injuries.

This increased safety and reduction in injuries is one of the main reasons that Sweed created the TS450 tube scarf chopper. “The results that we’re getting from the scarf chopper have been very good,” Charboneau says. “It has cut down on hand injuries because there’s less handling of the scarf.” In fact, Bull Moose Tube was able to reduce their hand injuries by 75%! Not only does this represent an incredible increase in workplace safety and employee satisfaction, but it also highlights how the ROI of a Sweed tube scarf chopper can be realized in the reduction of just one Worker’s Compensation Claim.

Beyond the obvious safety upside of a Sweed tube scarf chopper, the increase in line productivity is significant as well. The machine is custom-designed to fit into existing systems, accommodating a wide range of line speeds, from 300-feet per minute, up to speeds as fast 650-feet per minute or more. The continuous feeding of the scarf eliminates the need for repeated winder unloading. If you’re using a scarf winder, Charboneau explains, “when the winder is full, you have to stop, take the winding off, and throw it away.” This constant need to unload the winder caused a lot of inefficiency in the production line, which Sweed’s scarf chopper virtually eliminates with its line adaptability and ease of use.

Bull Moose Tube is a great example of just how powerful and innovative Sweed’s TS450 tube scarf chopper is. Not only has it helped the mill increase their worker safety and reduce the number of Worker’s Compensation Claims, but it has increased their line efficiency and allowed them to manufacture even more of their products for their clients around the world.