The Evolution of Wire Recycling: New Technologies in Copper Recovery

The Challenge of Modern Wire Recycling

Today’s wire chopping lines face increasingly complex challenges as material streams become more diverse and end-user specifications grow stricter. Processing facilities must handle everything from fine-gauge wire to heavy-duty cables while achieving higher purity rates than ever before. Additionally, rising operational costs and stricter environmental regulations have pushed the industry to innovate, developing new solutions that maximize efficiency while minimizing environmental impact.

Breaking Through Traditional Limitations

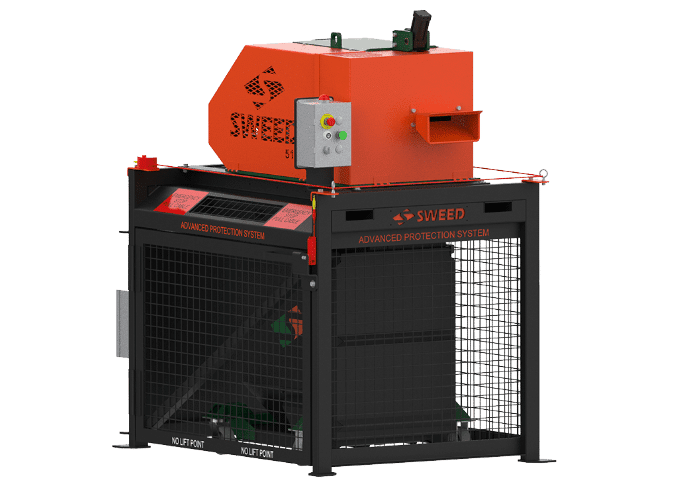

Modern wire chopping lines have evolved to become comprehensive processing solutions that combine multiple stages of material handling and separation. The process typically begins with initial size reduction through prechoppers and/or shredders, followed by granulation to to reduce the materials down to a consistent size for further separation. For despooling material from a reel, an industrial scrap chopper, such as the SWEED Model 5703 XHD, can seamlessly integrate into the wire chopping line to process cable on reels simultaneously, serving as an additional feed source. One of the most significant recent discoveries has been the development of specialized mills that can process fine copper wires, as seen in low-yield wire, more effectively than traditional methods, significantly improving nonferrous separation and reducing copper loss.

The Impact of Modern Technology

The industry has seen advancements in liberation technology, particularly in handling low-yield wire – historically one of the most challenging wires to process efficiently. New turbo mill systems can now:

- Convert straight wire hairs into pellet-like pieces

- Improve material flow through separation systems

- Enhance liberation of copper from insulation

- Increase throughput while maintaining quality

- Reduce system wear and maintenance needs

Processing Multiple Material Types

Today’s wire recycling systems must efficiently handle various materials:

- Transmission Wires

- Communication Cable

- Bare and Stranded Wires

- THHN

- ACSR

- ACSS

- BX and other armored cables

- ASR

- ACR and more

This versatility is crucial for recyclers dealing with evolving waste streams and market demands. Modern systems can adapt to varying input materials while maintaining high recovery rates, often processing multiple material types through the same line.

The Role of Automation and Control Systems

The integration of advanced control systems has transformed wire recycling from a largely manual process to a sophisticated, automated operation. Modern facilities employ real-time monitoring systems that track crucial process parameters and automatically adjust settings to optimize performance. This automation extends to every aspect of the operation, from initial feeding to final separation, resulting in more consistent output quality and reduced labor requirements.

Environmental and Economic Benefits

Technological advances have created a win-win situation for recyclers and the environment. Modern systems typically achieve recovery rates above 99% while consuming less energy per pound processed than older technologies. Advanced dust collection systems and environmental controls ensure cleaner operations, while improved separation technologies minimize waste sent to landfills.

Making the Right Investment

When evaluating new wire chopping line, consider:

- Current and projected material streams

- Required throughput rates

- Available facility space

- Return on investment calculations

- Future growth potential

The market offers solutions ranging from a simple chopping line to more comprehensive recycling systems containing multiple processing stages. While large-scale operations might benefit from a custom SWEED separation system designed for high throughput and to manage multiple material streams , smaller operators can start with more modest setups such as the SWEED S2000 or S2000+ and expand as needed.

As the industry continues to evolve, investing in modern recycling technology becomes increasingly crucial for maintaining competitiveness in a challenging market. Ready to learn more about modern wire recycling solutions? Contact industry experts to explore the latest technologies and find the right fit for your operation.