Engineering Excellence Across Industries

Recycling Equipment & Processing Solutions Since 1955

For over 70 years, SWEED has developed innovative solutions to address the unique challenges of diverse industries. Our engineering expertise and commitment to quality deliver results across a wide range of applications, from automated material handling to specialized recycling systems. Whether you need standard equipment or custom-engineered solutions, our team combines decades of experience with cutting-edge technology to optimize your operations. Every SWEED solution reflects our dedication to manufacturing excellence, proven reliability, and exceptional customer support.

Custom Engineered Solutions

Beyond Standard Applications

While we serve many established industries, our expertise in custom equipment design and fabrication means we can develop the perfect solution for your specific needs. Contact our engineers to discuss your specialized application requirements.

CUSTOM SOLUTIONSIncrease Efficiency & Safety

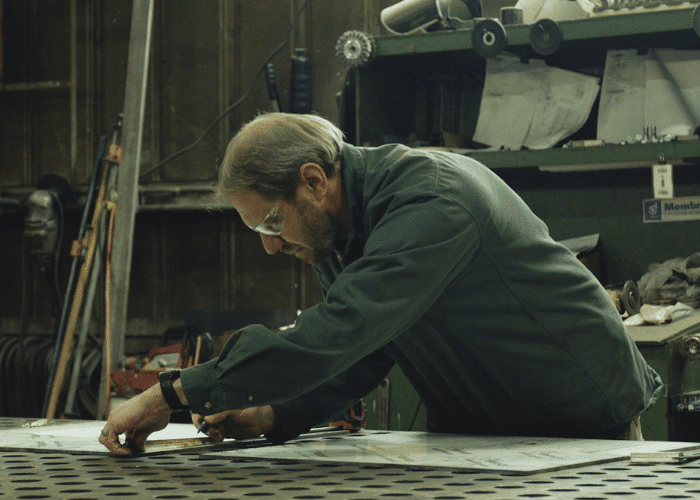

Metal Fabrication

Metal fabrication creates constant streams of challenging linear scrap that demands efficient processing. SWEED’s innovative solutions seamlessly integrate with your production line to increase safety, reduce costs, and maximize scrap value.

Innovation

Maximize Mill Productivity

Plywood & Veneer

From high-speed veneer operations to automated panel handling, SWEED’s material handling systems streamline production and optimize every phase of panel manufacturing.

Wire & Cable

SWEED’s wire and cable recycling systems define the industry standard for material processing. Our wire and cable recycling machines, combined with specialized wire and cable recycling separators, deliver superior copper and aluminum wire recycling results. Complete wire and cable recycling granulator solutions help maximize the value of your processing operation.

Recycled Materials

SWEED provides complete wire and cable recycling systems for scrap yards processing diverse material streams. From radiator recycling systems to nonferrous recycling granulators, our equipment handles everything from banded materials to bulk processing. We offer solutions for both ferrous and non-ferrous applications.

Warehousing & Distribution

Warehousing and distribution facilities face daily challenges managing large volumes of banding and strapping materials that create hazards and waste valuable space. Our scrap chopper equipment enhances workplace safety, reduces operational costs, and transforms packaging waste into recyclable assets.

Manufacturing

Modern manufacturing facilities need efficient ways to handle linear and bulk scrap materials. SWEED’s scrap choppers and steel band choppers seamlessly integrate with production lines to process packaging materials and metal trim. Our equipment enhances safety while improving plant cleanliness and material handling efficiency.

Wood & Lumber

SWEED’s comprehensive equipment line serves the wood products industry. Our panel feeders and automated grading lines enhance mill productivity, while our banding choppers and scrap choppers help processors manage materials safely and efficiently. From improving panel processing throughput to preventing equipment damage, SWEED equipment maintains efficient operations while maximizing valuable shop space.

Food & Beverage

Food and beverage operations face unique challenges managing packaging materials. SWEED’s strap choppers and steel band choppers efficiently process packaging waste, helping facilities reduce dumpster fees and achieve zero landfill goals while maintaining clean, safe operations.

Packaging

SWEED helps packaging operations efficiently manage high volumes of materials with our banding choppers and strap choppers. Our equipment reduces storage requirements for scrap materials while improving workplace safety and supporting sustainability initiatives through increased recycling.