Improve Your Scrap Processing

Transform your metalworking operations with SWEED’s scrap chopper solutions. From stamping and punch press operations to high-speed slitter lines, our equipment increases safety, improves efficiency, and maximizes the value of your metal scrap.

Metal fabrication creates constant streams of challenging linear scrap that demands efficient processing. Whether you need a steel banding chopper for debanding coils, a slitter trim chopper for production lines, or a cut-to-length chopper for precise material handling, SWEED’s solutions seamlessly integrate with your production line to process:

Punch press scrap

Stamping waste

Slitter trim

Edge trim

Heavy-gauge materials

Metal banding

Featured Solutions

High-Performance Equipment Tailored to Your Needs

SWEED's comprehensive line of scrap processing equipment easily handles metal fabrication recycling challenges. From stamping operations to high-speed slitter lines, we offer field-proven solutions that integrate seamlessly with your production processes to increase employee safety, reduce labor costs, and maximize scrap value.

Request A Quote

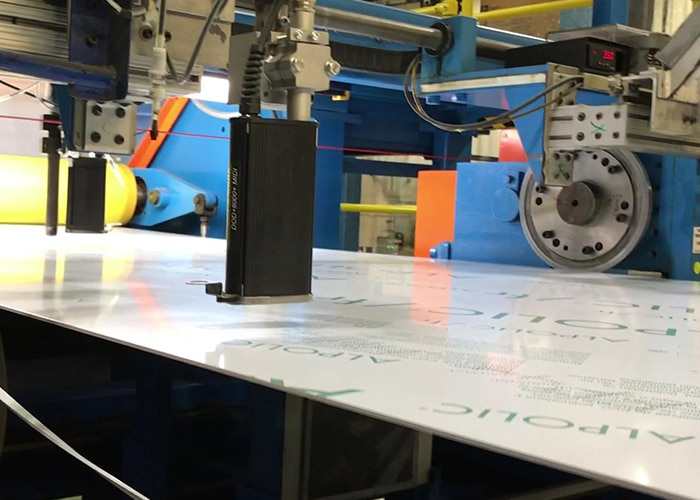

Model 450SL

Engineered for modern slitter line operations, the Model 450 SL eliminates the challenges of edge trim handling. This customized version of our proven Model 450 operates directly within your slitter edge trimming production line, typically featuring dual choppers that independently accommodate both sides of trim simultaneously. By eliminating the need for a scrap winder, this specialized slit trim chopper increases both production efficiency and employee safety.

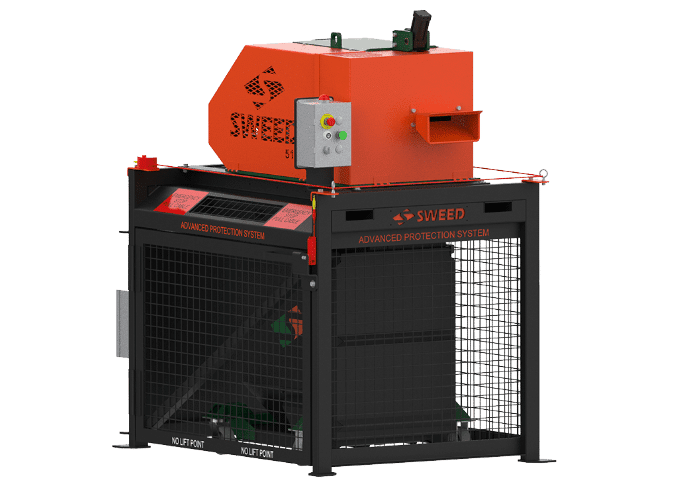

Model 510 XHD

For decades, metal fabricators have relied on the Model 510 XHD for high-volume scrap conversion. This workhorse consistently delivers quick, reliable processing of heavy-gauge materials while maintaining the flexibility to handle a variety of scrap types. Its dual-driven feedroll design ensures consistent material flow, while the robust cutting capacity handles your toughest applications.

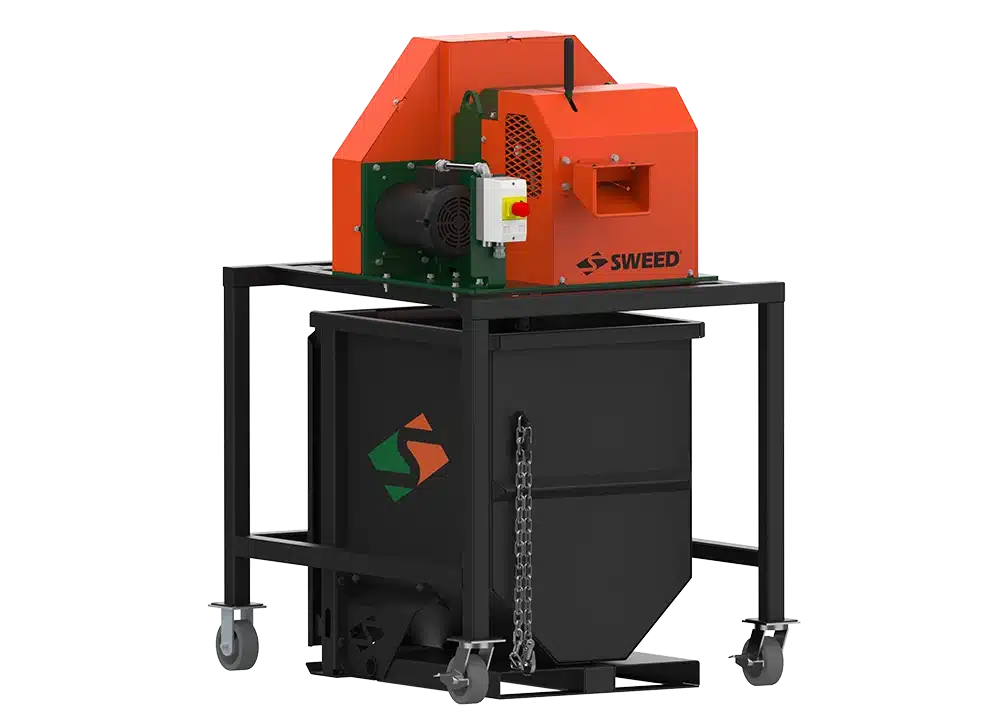

Model 480 Inline Systems

Purpose-built for integrated production line applications, the Model 480 delivers efficient scrap processing of slitter edge trim, punch press and stamping. This versatile unit seamlessly marries into manufacturing lines, eliminating the need for manual scrap handling while improving both safety and efficiency. Its wide infeed and variable speed capabilities make it ideal for slitter line and stamping applications.

Applications By Process

Slitter Line Operations

Continuous trim removal

Speed-matched processing

Automated scrap handling

Custom infeed options

Stamping Operations

High-volume scrap processing

Automated feed systems

Integration with press lines

Custom configurations

Heavy Gauge Processing

Robust processing capability

High-torque options

Specialized knife configurations

Enhanced safety features

Safety & Automation Features

More than just scrap chopping equipment, SWEED's solutions encompass complete workplace safety and automation considerations. Every system we design includes integrated safety features that protect operators while maximizing productivity.

Learn More