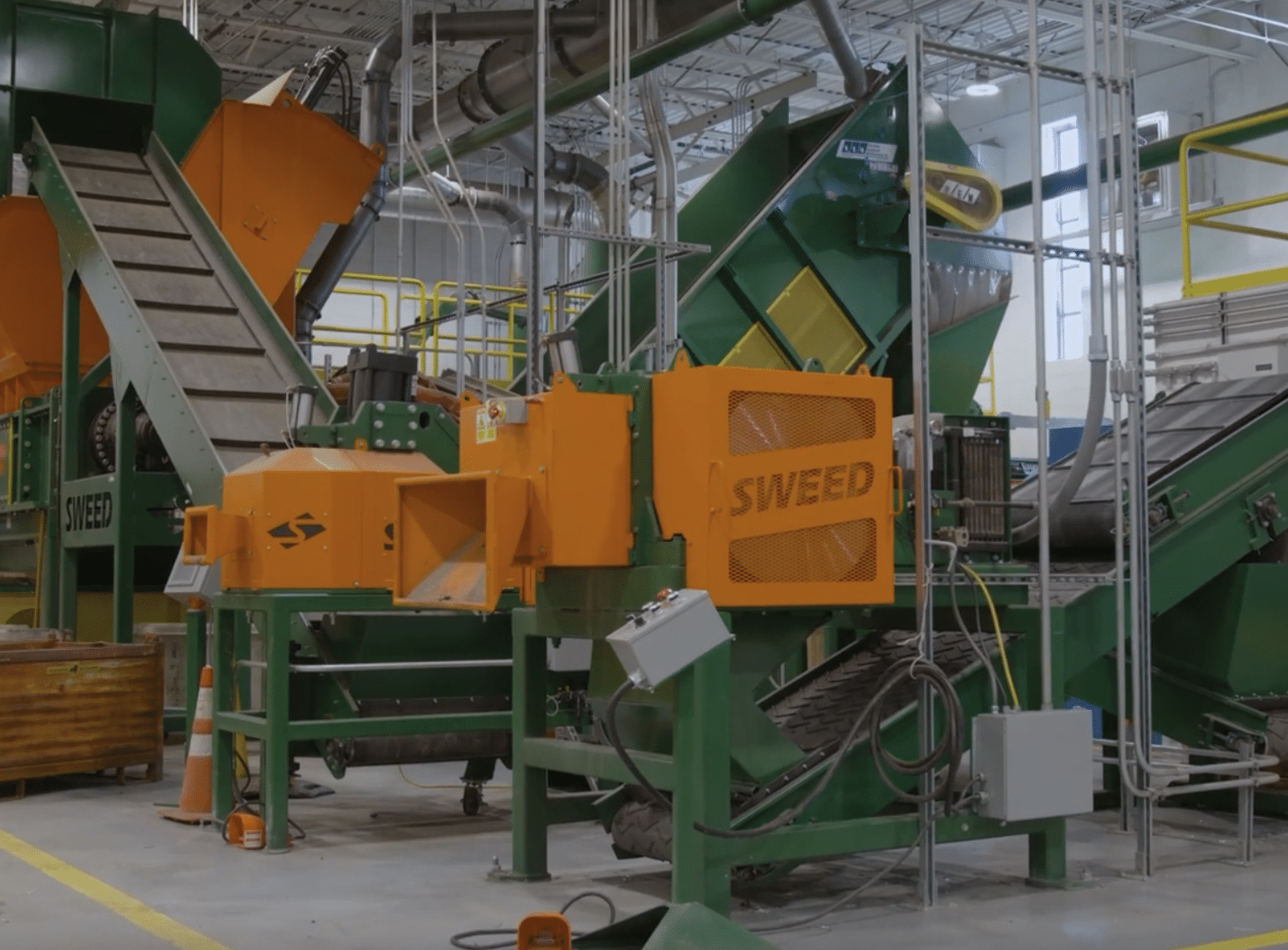

ACSR & ACSS Chopping Line

Efficient Chopping Line For ACSR and ACSS Of All Sizes.

SWEED’s ACSR system provides clean division of ferrous and non-ferrous materials. The system is capable of processing high volumes of ACSR and ACSS cable, or similar materials, using either the Model 5503 XHD, or Model 5703 XHD scrap chopper as the main processor.

CLICK HERE to learn how Bonneville Power chopped its way to recycling savings with a SWEED ACSR chopping line.

SWEED’s new inline separation systems uses high-power rare-earth magnets to separate all ferrous material from mixed material. Unlike the typical magnetic cross belt systems that are oriented perpendicular to the conveyor and have a high propensity to flip and drag material over the side of the belt and conveyor wall, the inline system gently removes the ferrous metal off the front of material being jammed between the belt and conveyor since the material is never dragged sideways off the conveyor belt. Depending on space requirements, SWEED’s inline separation system can be coupled with a high-intensity rare earth magnet secondary pass system taking product purity to 99.99%. This ensures the end product to be virtually free of ferrous material that may downgrade and prevent it from selling at optimal market value.

Recyclers handling ACSS cable can combine SWEED’s ACSR system with SWEED’s VR4K preprocessor. The VR4K is highly effective at removing the much softer aluminum layer present on ACSS cables. This initial aluminum layer removal significantly enhances the efficiency of processing and the subsequent separation of the remaining cable layers through the secondary scrap chopper.

Construction Features

SWEED systems feature robust designs and seamless integration capabilities that optimize cable separation through innovative technology. This results in maximum scrap metal recovery, simplified system maintenance, and durable construction.

UL508A Control Cabinet

Durable and built to withstand harsh environments

High purity end results

Simple and minimal maintenance required

SECONDARY STATIC MAGNET TO CATCH STEEL FINES MISSED IN THE INITIAL PASS