Maximize Your Material Recovery

SWEED’s wire chopping lines will transform your scrap processing capabilities. From wire and cable to ACR’s, our equipment delivers superior recovery rates while maintaining high purity standards.

Modern recycled materials facilities need versatile equipment to handle diverse material streams efficiently. SWEED’s recycling systems process:

#1 ICW and #2 ICW

Wire harnesses

ASR

ACR

ACSR/ACSS Materials

Transmission Wires

Communication Cables

Featured Solutions

Increase Your Recovery Value

SWEED's recycling equipment is built to tackle a range of scrap processing challenges, handling both bulk and linear materials. Our recycling systems and nonferrous recycling granulators specialize in copper and aluminum recovery, while our linear scrap choppers efficiently process materials by chopping them into small, manageable pieces. This provides exceptional compaction, reduces logistics costs, and ensures the material is ready for the next stage of recycling.

Request A Quote

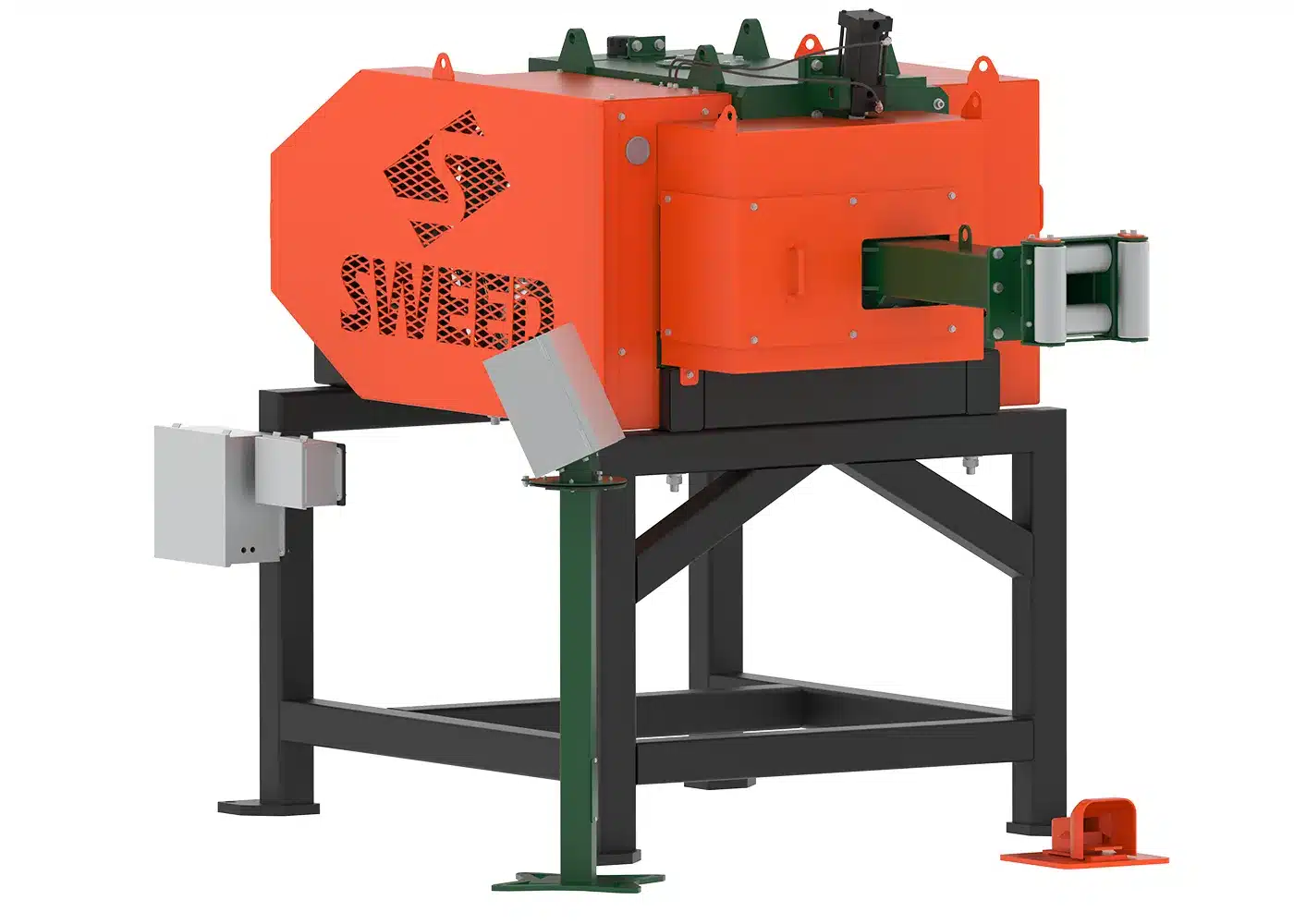

Model 5703 XHD

Our solution for the most demanding scrap processing applications delivers unmatched performance in high-production environments. This remarkably tough scrap chopper brings together decades of engineering expertise to handle everything from high-tensile wire to communication cables. The unique front-opening feedworks and robust construction ensure reliable operation in demanding scrap yard environments.

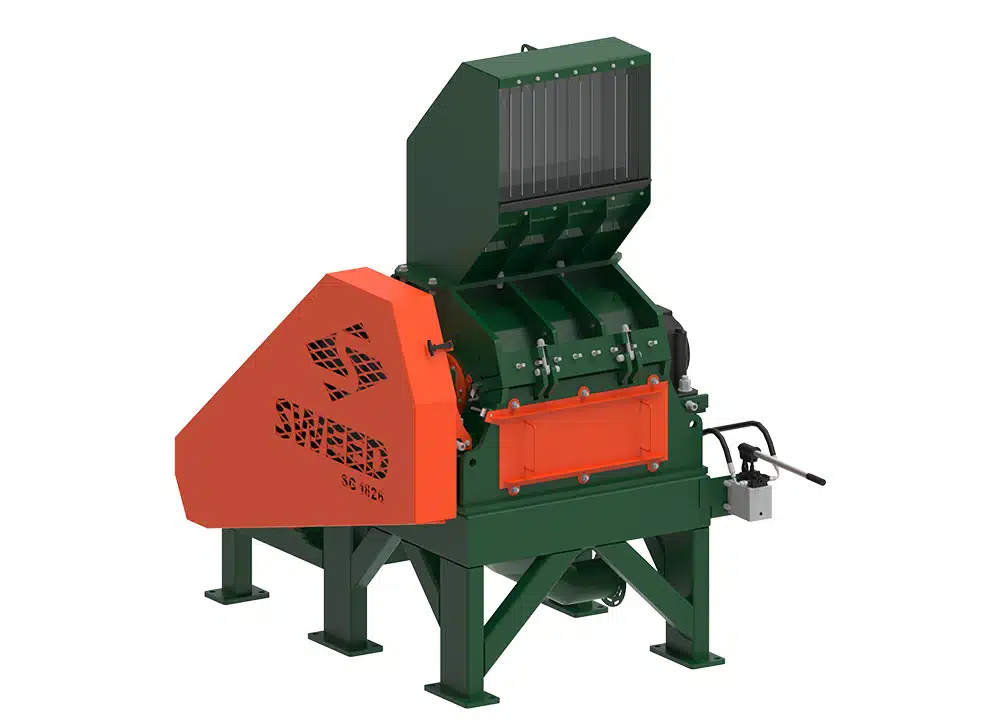

SG Series Granulators

Built for demanding scrap applications, our recycling granulators deliver superior size reduction while preparing materials for downstream separation. Granulators are typically integrated within a chopping line, used for secondary size and volume reduction, but can also be used as a standalone machine. Available in multiple sizes to match your throughput requirements, from the SG1826 to the high-capacity SG1840.

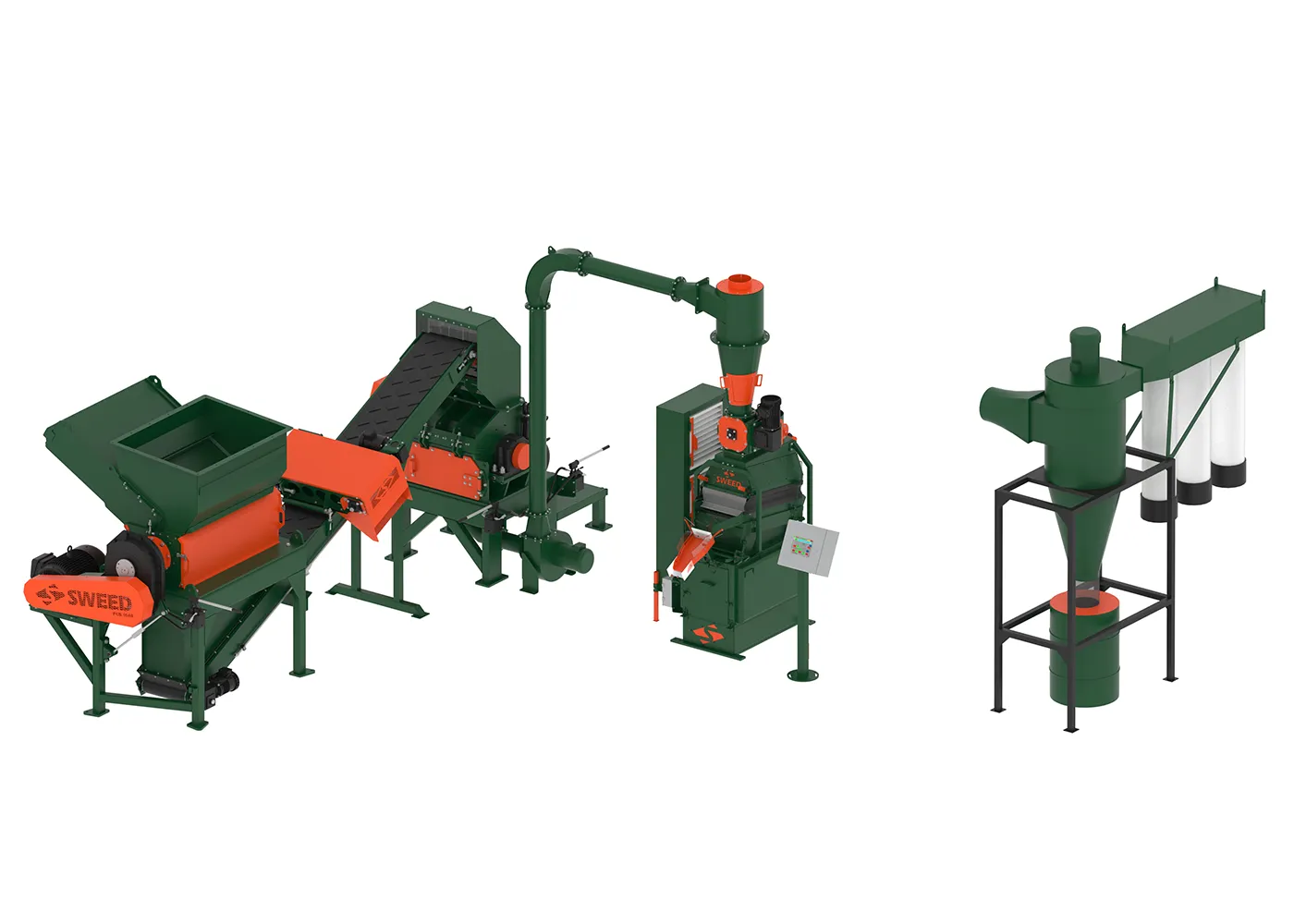

S2000 Series Wire Chopping Line

SWEED’s standard chopping line systems, the S2000 and S2000+, deliver exceptional material recovery within a compact footprint. These complete wire recycling systems process up to 2,000 pounds per hour of various materials, from #1 ICW to challenging low-yield wire. The S2000+ features an integrated turbo mill and dual dedicated air tables, allowing simultaneous processing of copper and aluminum materials through our specialized nonferrous recycling granulators. Both systems are designed with adaptability in mind, easily incorporating additional components as your processing needs expand.

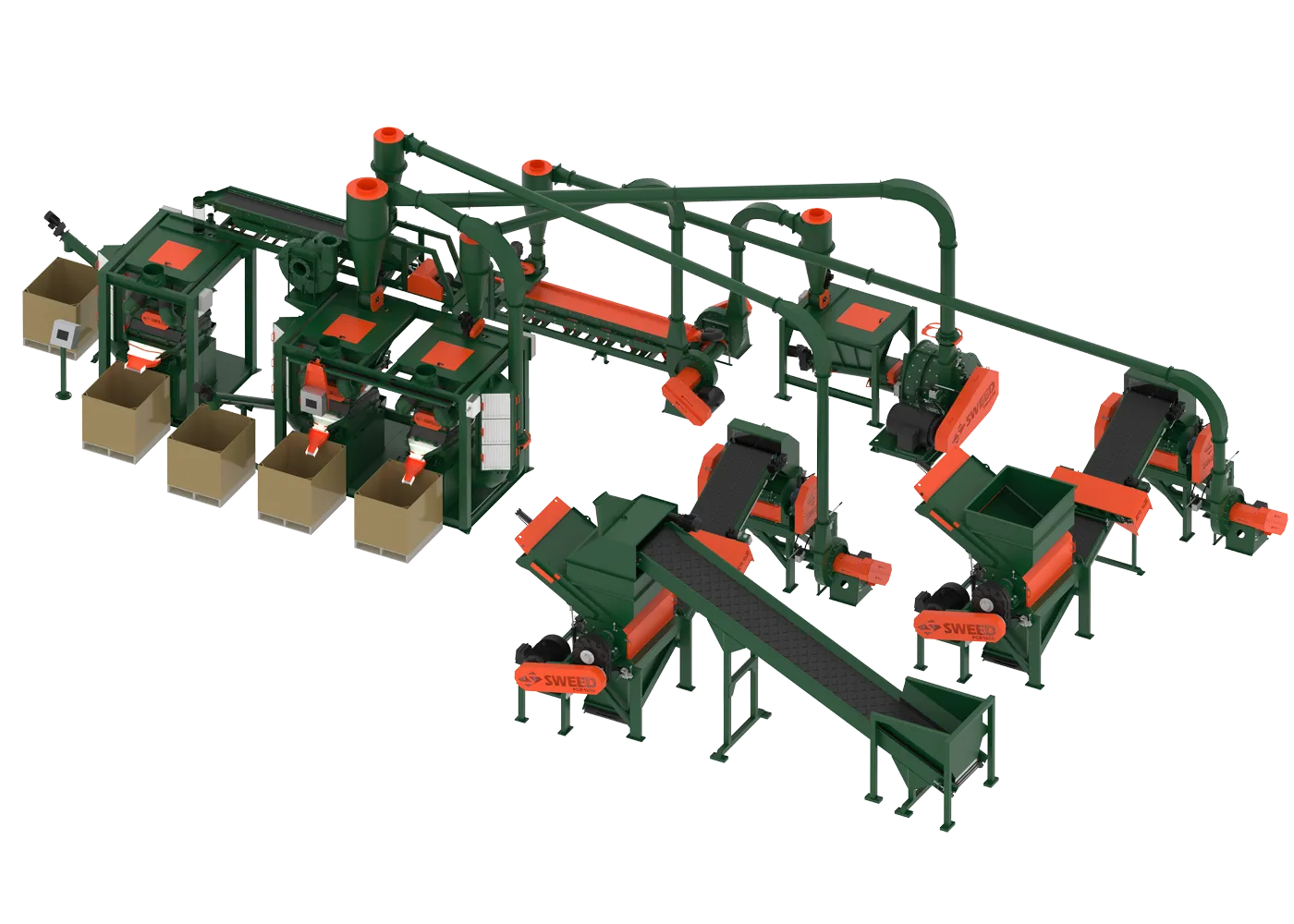

Custom Chopping Lines

For facilities needing additional processing power, SWEED specializes in crafting customized chopping lines that precisely match your material specifications, footprint, and output requirements.

Our robust processors are designed for efficient recovery of copper and aluminum across operations of all sizes. They are built to handle a wide range of materials, including power and communication cables, ASR, ACR, ACSR, BX cable, and wire harnesses. From complete wire and cable recycling systems to specialized wire granulators, we provide tailored solutions that consider your available space, material types, throughput needs, and purity standards, ensuring optimal performance for your unique recycling demands.

Applications By Process

Wire & Cable Processing

High-volume material handling

Maximum copper and aluminum recovery

Premium-grade outputs

Nonferrous Recovery

Multi-stage processing

Maximized recovery rates

High-purity results

Industrial Scrap

Versatile material handling

Reliable size reduction

Consistent performance

Safety & Automation Features

Processing diverse scrap streams demands robust safety systems. SWEED's equipment incorporates safety features specifically designed for scrap yard environments, from emergency stops to advanced material handling protection. Our systems help maintain OSHA compliance while protecting operators from the unique hazards of recycled materials processing.

Learn More