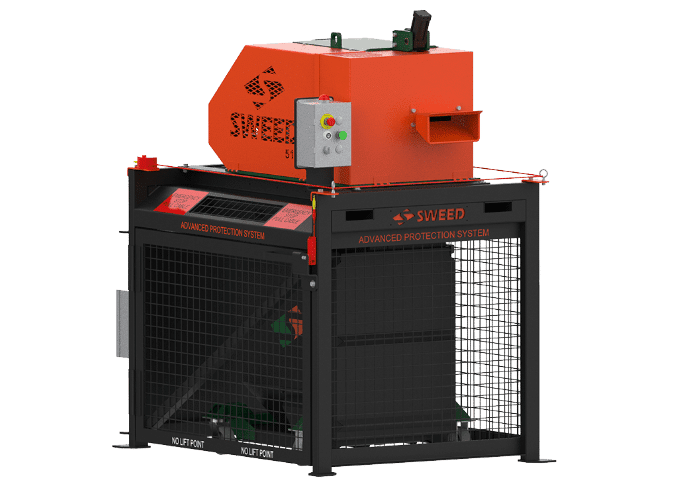

Model 450 DDX

$5,395.00Add to cart

Key Features

- Dual driven feedworks increases feeding efficiency and throughput

- Versatile performance for high volumes of strapping

- Heavy-duty construction designed for years of continuous service

- Chopper, stand, and hopper sold separately

Product Description

Dual Driven Feedworks Increases Feeding Efficiency.

The Model 450 DDX boasts power alongside a dual-driven feedworks. Driving both feed rolls on the chopper allows the unit to process scrap quickly and efficiently.

The Model 450 DDX is SWEED’s chopper of choice for companies processing large volumes of scrap plastic or PET strapping. This chopper is extremely versatile and can be customized for inline automated production applications requiring tension control and custom scrap lengths. The Model 450 DDX is designed to fit on several SWEED stands that can accommodate a variety of scrap collection containers. Custom stands and additional safety upgrades are also available.